In the fast-paced world of electronics development, time is more than money—it’s your competitive edge. After years of working closely with engineering teams, we’ve heard the same challenge repeatedly: PCB design creates bottlenecks that slow down innovation.

That’s why we’re excited to announce our game-changing new application.

Our team has developed an intelligent PCB automation solution that transforms what traditionally takes days into a process completed in under an hour.

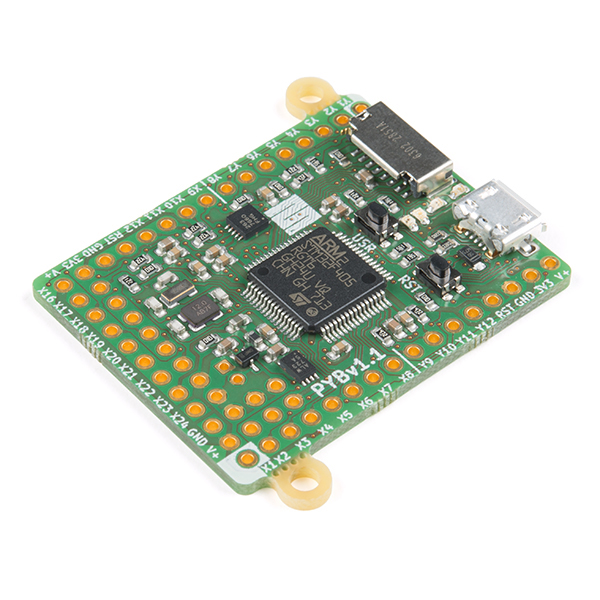

Automated PCB Flow diagram

Through advanced algorithms, we’ve created a system that handles placement and routing with minimal human intervention while maintaining complete design integrity. For more details visit AutoCuro

What makes this different?

Unlike conventional PCB design tools that require extensive manual work, our application intelligently analyzes your requirements and constraints to generate optimal layouts automatically. This isn’t just another iteration of existing tools—it’s a fundamentally different approach to PCB creation.

The system is particularly valuable for teams juggling multiple designs across various tools. No more waiting for specialized engineers to become available or dealing with design inconsistencies between team members.

Be among the first to transform your design process

We’re currently opening limited beta access to selected partners who understand the value of dramatically accelerated design cycles. Early adopters will have direct input into future features and priority support from our expert team.

Interested in cutting your PCB design time by up to 75%?

Visit our contact page to express your interest in the beta program. Our team will reach out personally to qualified applicants.

The future of PCB design is here—and it’s measured in minutes, not days.